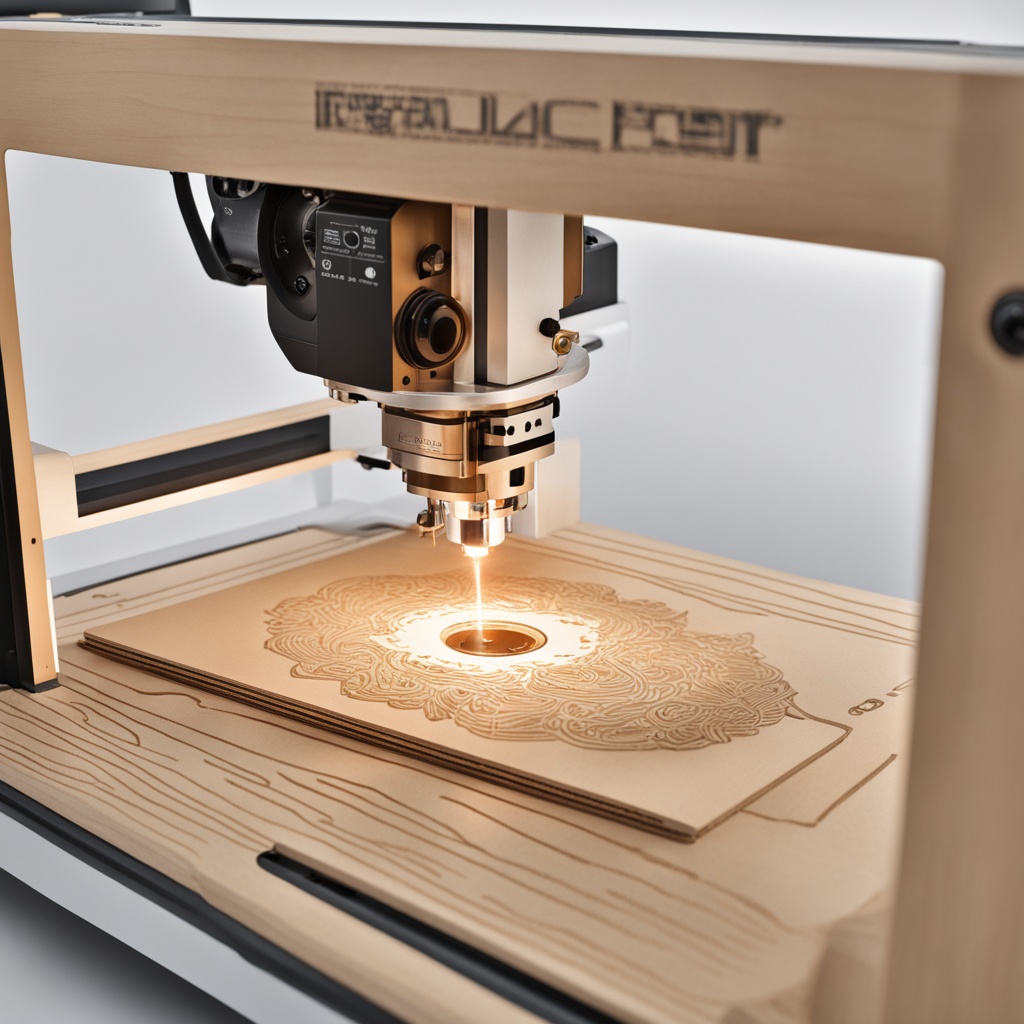

The Best Fiber Laser Engraving Machine for Home Use: A Comprehensive Guide

Fiber laser engraving machines are revolutionizing the way we create intricate designs and markings on various materials. With their precision, speed, and versatility, these machines have become a favorite among hobbyists, crafters, and professionals alike. If you’re considering investing in one for your home or small workshop, this guide will help you understand everything you need to know about fiber laser engraving machines.

Why Choose a Fiber Laser Engraving Machine?

Fiber laser engraving machines are a popular choice due to their ability to handle a wide range of materials with ease. Whether you’re working with metal, wood, plastic, or even glass, these machines can deliver precise and detailed engravings. Unlike traditional methods that require physical contact with the material, fiber lasers use light beams to create designs without causing wear and tear on your tools.

One of the key advantages of a fiber laser engraving machine is its speed. It can complete complex designs in a fraction of the time it would take manually. This makes it an excellent choice for both small-scale projects and larger production runs. Additionally, these machines are easy to use, even for beginners, thanks to their intuitive interfaces and user-friendly software.

If you’re wondering, “What materials can I engrave with a fiber laser machine?” The answer is almost anything! From metal to wood, these machines are capable of handling various surfaces with ease. However, it’s important to note that the type of material will influence the settings you use for optimal results.

The Benefits of Using a Fiber Laser Engraving Machine

There are numerous benefits to using a fiber laser engraving machine, especially for home or small-scale use:

- Precision and accuracy: Fiber lasers can create intricate designs with micron-level precision, ensuring every detail is perfectly executed.

- Versatility: These machines work with a wide range of materials, making them ideal for various projects.

- Speed: Compared to traditional engraving methods, fiber lasers are much faster, saving you time and effort.

- Low maintenance: Fiber laser systems require minimal upkeep, reducing long-term costs and hassle.

These benefits make a fiber laser engraving machine an excellent investment for anyone looking to enhance their crafting or prototyping capabilities at home.

Key Features of a Fiber Laser Engraving Machine

When selecting the best fiber laser engraving machine for your needs, there are several features to consider:

- Laser Power: Higher power lasers are better suited for thick or dense materials like metal, while lower power lasers are ideal for thinner materials such as wood or plastic.

- Engraving Area: The size of the engraving area determines how large your projects can be. Choose a machine that aligns with your project requirements.

- User Interface: A user-friendly interface and software make it easier to design and control your engravings, even for those new to laser cutting.

- Dust Extraction System: A good dust extraction system ensures clean and safe operation by removing particles generated during engraving.

By considering these features, you can choose a machine that best fits your needs and budget. For example, if you’re primarily working with metal, a higher power laser would be essential. On the other hand, if you’re focused on crafting smaller, intricate designs, a lower power laser might suffice.

How to Use a Fiber Laser Engraving Machine

Using a fiber laser engraving machine is relatively straightforward once you understand the basics:

- Design Your Project: Create your design using laser-compatible software or import an existing file. Ensure the design is optimized for the material you’re working with.

- Prepare Your Material: Clean and secure your material in place on the machine’s bed. Properly securing your material prevents movement during engraving, which could lead to errors.

- Set Up the Machine: Adjust the laser settings according to your material type and design complexity. This includes setting the power level, speed, and focal length.

- Start Engraving: Once everything is set up, you can start the engraving process. Monitor the machine to ensure it’s working correctly and make adjustments as needed.

If you’re wondering, “How do I achieve the best results with my fiber laser machine?” The key lies in experimenting with different settings and materials. Practice on scrap material before tackling your final project to get a feel for how the machine performs under various conditions.

Maintenance Tips for Your Fiber Laser Engraving Machine

Proper maintenance is essential to ensure your fiber laser engraving machine operates efficiently and lasts for years. Here are some tips:

- Clean Regularly: Dust and debris can accumulate on the machine’s surfaces, lenses, and mirrors. Clean these components regularly using a soft cloth or compressed air.

- Check for Wear: Inspect belts, pulleys, and other moving parts for signs of wear and replace them as needed.

- Calibrate the Machine: Periodically calibrate your machine to ensure accurate engraving. This helps maintain consistent results over time.

- Follow Manufacturer Guidelines: Refer to your machine’s user manual for specific maintenance instructions and schedules.

By taking care of your fiber laser engraving machine, you can extend its lifespan and ensure it continues to deliver high-quality results for all your projects.

Applications of Fiber Laser Engraving Machines

Fiber laser engraving machines are incredibly versatile and can be used in a wide range of applications:

- Metal Engraving: Create custom designs on metal surfaces for jewelry, signage, or decorative items.

- Wood Cutting and Engraving: Use the machine to cut intricate patterns in wood or engrave detailed designs for furniture, gifts, or home decor.

- Plastic Prototyping: Quickly create prototypes from plastic materials for product development or testing.

- Glass Etching: Achieve professional-quality etchings on glass surfaces for custom windows, mirrors, or decorative items.

These applications demonstrate the versatility of a fiber laser engraving machine and its ability to handle various materials and projects. Whether you’re working on a small-scale craft project or a larger production run, these machines offer unmatched precision and efficiency.

Frequently Asked Questions About Fiber Laser Engraving Machines

If you’re new to fiber laser engraving, you may have several questions:

- Is a fiber laser engraving machine safe to use? Yes, as long as you follow safety guidelines and wear appropriate protective gear like goggles and gloves.

- How much does a fiber laser engraving machine cost? Prices vary depending on the model and features, but you can find affordable options for home use starting at around $500.

- Can I upgrade my machine later? Yes, many machines allow for upgrades such as additional lasers or software enhancements to expand their capabilities over time.

If you’re still unsure about whether a fiber laser engraving machine is right for your needs, consider starting with a smaller model or renting one to get hands-on experience before making a purchase.

The Future of Fiber Laser Engraving Machines

Fiber laser technology continues to evolve, offering even more possibilities for creators and manufacturers. As the demand for precision and efficiency grows, we can expect to see further advancements in laser engraving machines, including increased speed, higher accuracy, and new material compatibility options.

If you’re looking to stay ahead of the curve or simply enhance your creative capabilities, investing in a fiber laser engraving machine is a wise choice. With its versatility and ease of use, it can open up endless opportunities for innovation and production in both personal and professional settings.

Conclusion

A fiber laser engraving machine is an invaluable tool for anyone looking to create precise, high-quality engravings or cuts on a variety of materials. With proper setup, use, and maintenance, these machines can handle everything from small-scale crafting projects to large-scale industrial applications. Whether you’re a hobbyist, artist, or business owner, a fiber laser engraving machine offers the flexibility and performance needed to bring your ideas to life.

If you’re ready to take your creative or production capabilities to the next level, consider adding a fiber laser engraving machine to your arsenal. It’s an investment that can pay off in terms of time saved, quality results, and the ability to tackle complex projects with ease.