“

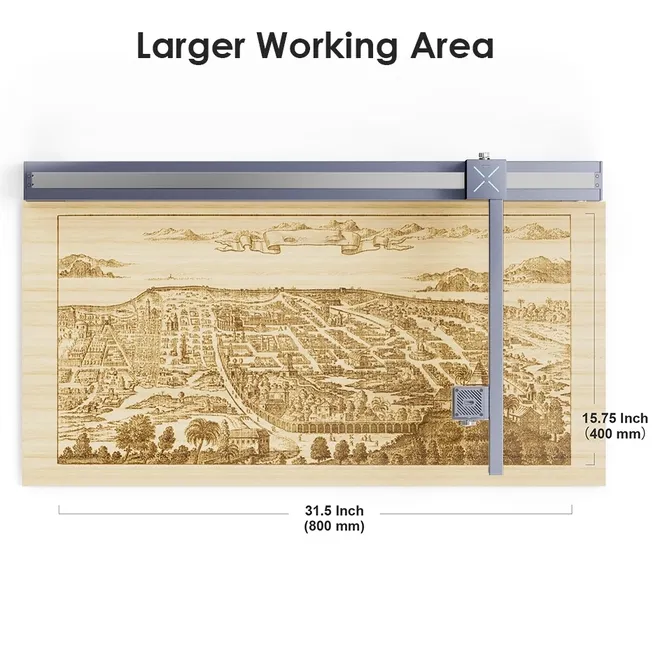

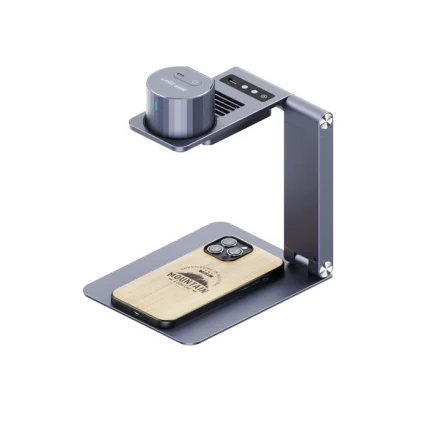

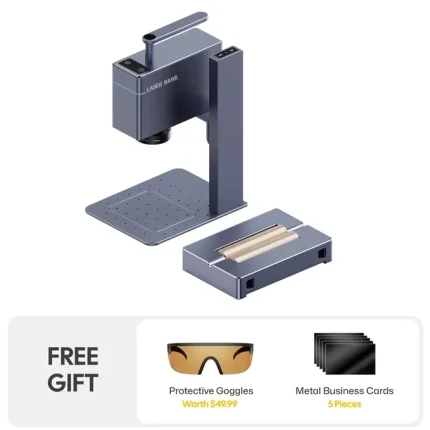

Discover the ultimate precision and versatility with the LaserHawk LX1 Series, the best laser engraving machine designed for both hobbyists and professionals. Whether you’re crafting intricate designs on wood, cutting acrylic with unmatched accuracy, or offering laser cutter service to clients, the LX1 Series delivers exceptional performance every time.

This state-of-the-art laser acrylic cutter combines cutting-edge technology with user-friendly features, making it the perfect addition to your home workshop or small business. With its robust build and advanced laser capabilities, the LaserHawk LX1 Series ensures flawless results on a variety of materials, including wood, acrylic, leather, and more.

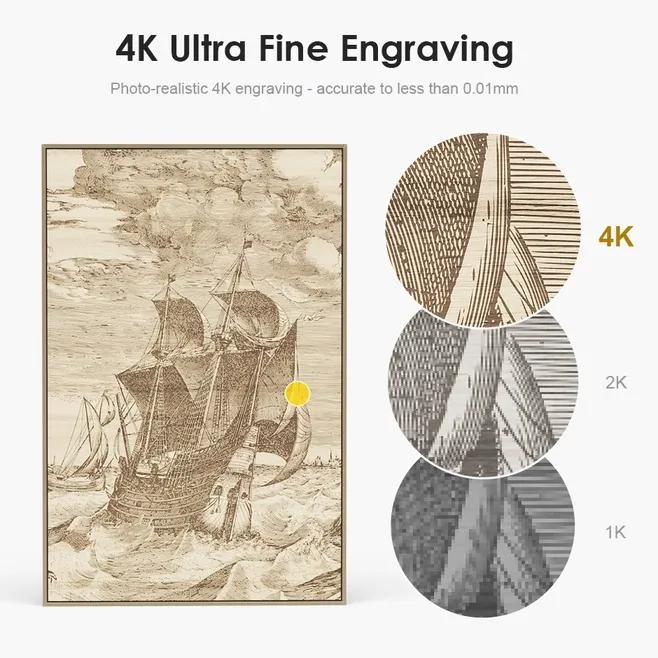

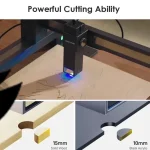

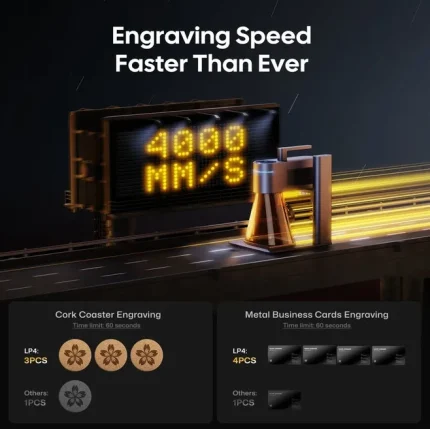

- High-Precision Laser Engraving: Achieve intricate details and sharp edges with the LX1’s advanced laser system, perfect for custom designs and professional-grade projects.

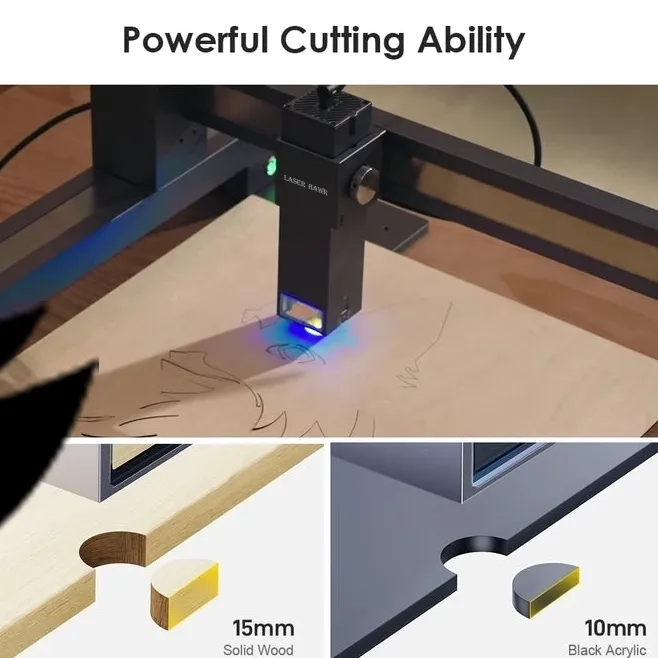

- Versatile Material Compatibility: From wood and acrylic to glass and metal, this machine handles it all, making it the ultimate laser cutter service tool.

- User-Friendly Interface: Designed for ease of use, the LX1 Series features intuitive controls and software compatibility, ensuring a seamless experience for beginners and experts alike.

- Compact and Durable Design: Built for home use, the LX1 Series is compact yet durable, offering reliable performance without taking up too much space.

- Eco-Friendly Operation: With energy-efficient technology and minimal waste, the LX1 Series is an environmentally conscious choice for your creative endeavors.

Transform your creative vision into reality with the LaserHawk LX1 Series, the best laser engraving machine for home use. Whether you’re a DIY enthusiast or a professional offering laser cutter service, this machine is your gateway to unparalleled precision and innovation.

Upgrade your toolkit today and experience the future of laser engraving and cutting with the LaserHawk LX1 Series!

More you like:

Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser engraving✓Laser cutter machine✓Laser engraver engraving machine✓LaserHawk LH2 | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Laser engraver machine✓ Fiber laser engraver✓Laser engraver for metal✓LaserHawk LH3

Soo Lee –

This laser engraver delivers stunning detail and precision. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable. 5 stars!

Deborah Rossi (verified owner) –

**Experience with Laser Engraver in Product Prototyping**

In my work with product prototyping, I have utilized a laser engraver primarily for creating artistic wall pieces, which involved intricate designs on wood and acrylic materials. The laser’s precision was exceptional, capable of achieving fine details that enhanced the aesthetic appeal of each piece.

**Specific Project Experience:**

– **Materials:** Wood and acrylic were the primary materials used. The laser demonstrated high precision, particularly in carving complex patterns.

– **Challenges & Solutions:** Encountered minor burn marks on wood and slight warping in acrylic. Adjusting power settings for wood reduced burning, while using sacrificial layers on acrylic minimized warping.

**Technical Performance:**

– **Power Settings:** The engraver’s adjustable power (up to 100W) allowed fine-tuning for different materials, ensuring optimal results without damage.

– **Software Features:** The user-friendly software provided tools like vector tracing and raster engraving. Custom settings were crucial for maintaining consistency across projects.

**Impact on Workflow:**

The integration of this laser engraver significantly improved efficiency, enabling precise and consistent output that met high-quality standards. Customer feedback was overwhelmingly positive, praising the intricate details and durability of the engravings.

This experience underscored the importance of both technical capabilities and material understanding in achieving successful prototyping outcomes with a laser engraver.

Mei Johnson –

“This laser engraver exceeds expectations! Exceptional engraving precision and detail. The machine’s operability and software ease make it a breeze to use. Highly reliable and efficient.”